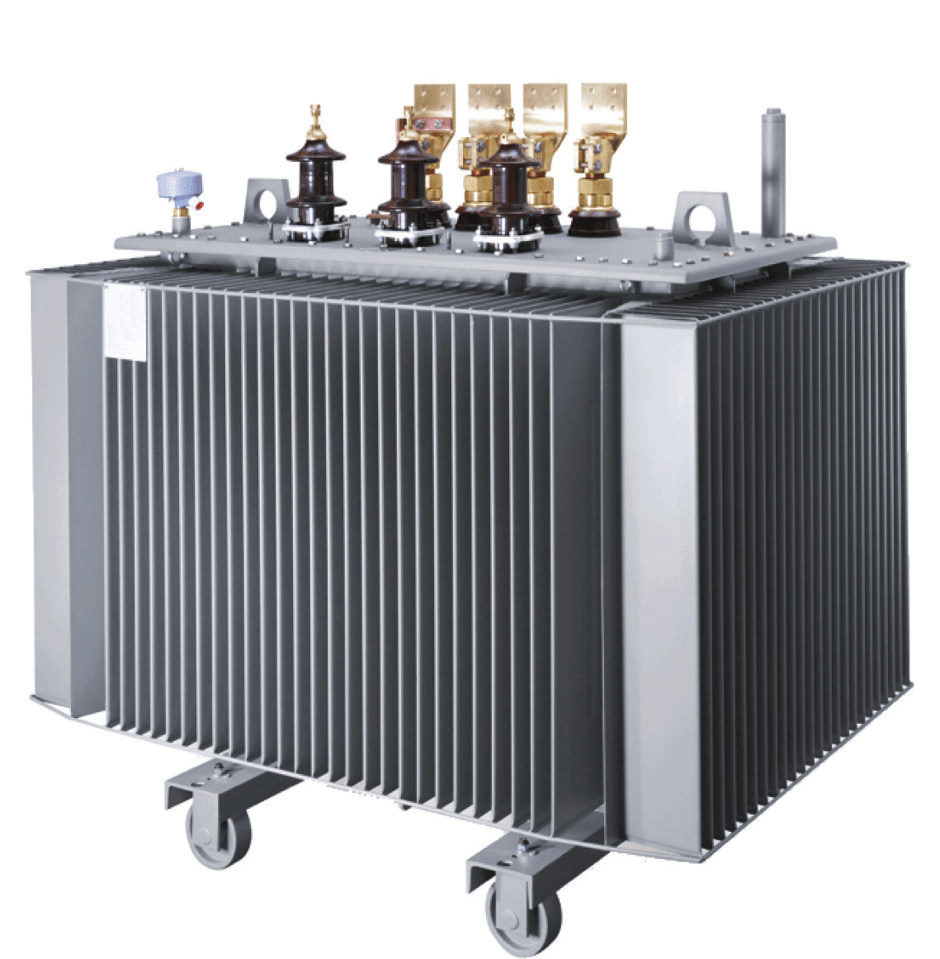

Corrugated and conservator type oil-immersed transformers developed and designed in accordance with international standards (IEC, VDE, & BS)

- Multi-step lap, grain-oriented, cold-rolled, silicon alloyed, electric sheet steel core with insulation on both sides

- Strip or flat-wire low-voltage copper or aluminum windings

- Round or profile wire elliptical high voltage copper or aluminum windings

- Epoxy resin coated insulation paper

- Large scale winding oil channels

- Multi-coat surface protection tailored to client operating requirements

- Low losses

- Low noise

- High reliability

- Superior return on investment

- Substations

- Compact substations

- Industrial facilities

- Special uses (converter/earthing)

- Low core mechanical tension

- Winding protection against electrical and mechanical stress

- Ample cooling for elimination of winding hot spots

- Short-circuit and surge proof

- External protection against corrosion, temperature fluctuations, humidity and other environmental factors

- Easy to handle, operate and maintain

Product Specification

| Type | Hermetically sealed with or without gas cushion Breathing type with or without conservator |

|---|---|

| Rated Power | Up to 6.3 MVA |

| Voltage Class | Up to 36 kV |

| Tank Construction | Corrugated fin wall tank or plain wall tank with radiator (Bolted or welded cover) |

| Winding Material | Copper/ Copper, Aluminum/ Aluminum (or as requested) |

| Basic Insulation Level | Up to 200 kVp |

| Phases | 3 Phase |

| Tappings | 2± x 2.5 % (or different range or as requested) |

| Voltage Regulations | With off-circuit tap changer |

| Rated Frequency | 50 Hz or 60 Hz |

| Vector Groups | According to IEC standards |

| Material Thermal Class Insulation | According to IEC 60085 class A |

| Temperature Rise | As per IEC 60076 or as requested |

| Type of Cooling | ONAN (Oil Natural Air Natural) or other type of cooling like ONAF, KNAN |

| Dielectric Liquid | Mineral oil according to IEC standard, silicon oil or synthetic ester |

| Short-circuit Withstand Ability | The transformers are designed to withstand the thermal and the dynamic effects resulting from a secondary short-circuit in accordance with IEC 60076-5 |

| Sound Level | EC 60076-10 or NEMA – TR1 or as requested |

| Installations | Indoor or outdoor |

| HV/ LV Terminals | HV Terminals: Plug-in or porcelain bushings with or without cable box

LV Terminals: Cast resin, bar type or porcelain bushings with or without cable box, Cable box if required can be air insulated or fully insulated as per BS EN 503366:2002,(IP55 class or as requested) |

Accessories

- Oil level indicator

- Skid under-base

- Valves

- Thermometer pocket

- Buchholz relay (with conservator)

- Dehydrating breather

- Magnetic oil level gauge (with conservator)

- Off circuit tap changer

- HV and LV bushings

- Rating and diagram plate

- Lifting lugs

- Earthing terminal

- Haulage lug

- Lashing lug

- Oil temperature indicator

- Winding temperature indicator

- Pressure relief device

- DGPT

- Marshalling box/ Terminal box

- Bi-directional roller

- Jacking pad

- CT

Type-test Reports

|

SL. NO |

Power Rating (kVA) |

Voltage (kV) |

Certificate No. |

Certification Agency |

Tank Construction |

|

1 |

1000 |

22 |

18940 |

ASTA |

Corrugated |

|

2 |

500 |

22 |

18726 |

ASTA |

Corrugated |

|

3 |

2000 |

22 |

A9030609 |

CESI |

Corrugated |

|

4 |

1500 |

22 |

B0033628 |

CESI |

Corrugated |

|

5 |

1500 |

33 |

18941 |

ASTA |

Corrugated |

|

6 |

1000 |

11 |

18475 |

ASTA |

Corrugated |

|

7 |

1600 |

11 |

18474 |

ASTA |

Corrugated |

|

11 |

1500 |

11 |

B0001743 |

CESI |

Corrugated |

|

12 |

1000 |

11 |

A9036863 |

CESI |

Corrugated |

|

13 |

500 |

11 |

A9007545 |

CESI |

Corrugated |

|

14 |

200(PMT) |

11 |

B0001838 |

CESI |

Corrugated |

|

8 |

1000 |

11 |

18656 |

ASTA |

Radiator Type |

|

9 |

1600 |

11 |

18657 |

ASTA |

Radiator Type |

|

10 |

1250 |

11 |

TIC 2060-12 |

KEMA |

Radiator Type |